Infant milk powder production is very demanding and requires high-tech production equipment, in order to comply with French and international standards.

With a view to pursuing its development, Isigny Sainte-Mère is constantly optimising its production tools dedicated to infant milk.

These high standards, combined with the know-how of our experts, enable us to offer our customers products that are highly technical and tailor-made.

In order to remain at the forefront of the market in terms of technology and quality, we have 5 spray drying towers and 2 ultra-modern packaging lines.

Approximately 2.5 million babies are now fed every day with infant formula milk powder produced by Isigny Sainte-Mère.

In 2015, a new production facility, called U2, was opened on the Isigny-sur-Mer site to ramp up production.

drying towers

drying towers

packaging lines

packaging lines

m² of floor area

m² of floor area

As a result of the confidence placed in us by our customers, a new production facility is now required in order to meet demand.

Scheduled for summer 2021, the new U3 production facility will enable us to remain at the cutting edge of technology by increasing our annual production capacity from 42,000 to 70,000 tonnes of infant milk formula.

This new site, with a floor area of 11,000 m², will include a drying tower with a production capacity of 4 tonnes an hour and a dedicated packaging line, which will continue to offer the same guarantee of excellence.

When construction is completed for its new infant formula milk powder production facility, our Cooperative will have the largest production site in Europe, exclusively for bespoke use for our B2B customers.

More information about projects can be found in the News section.

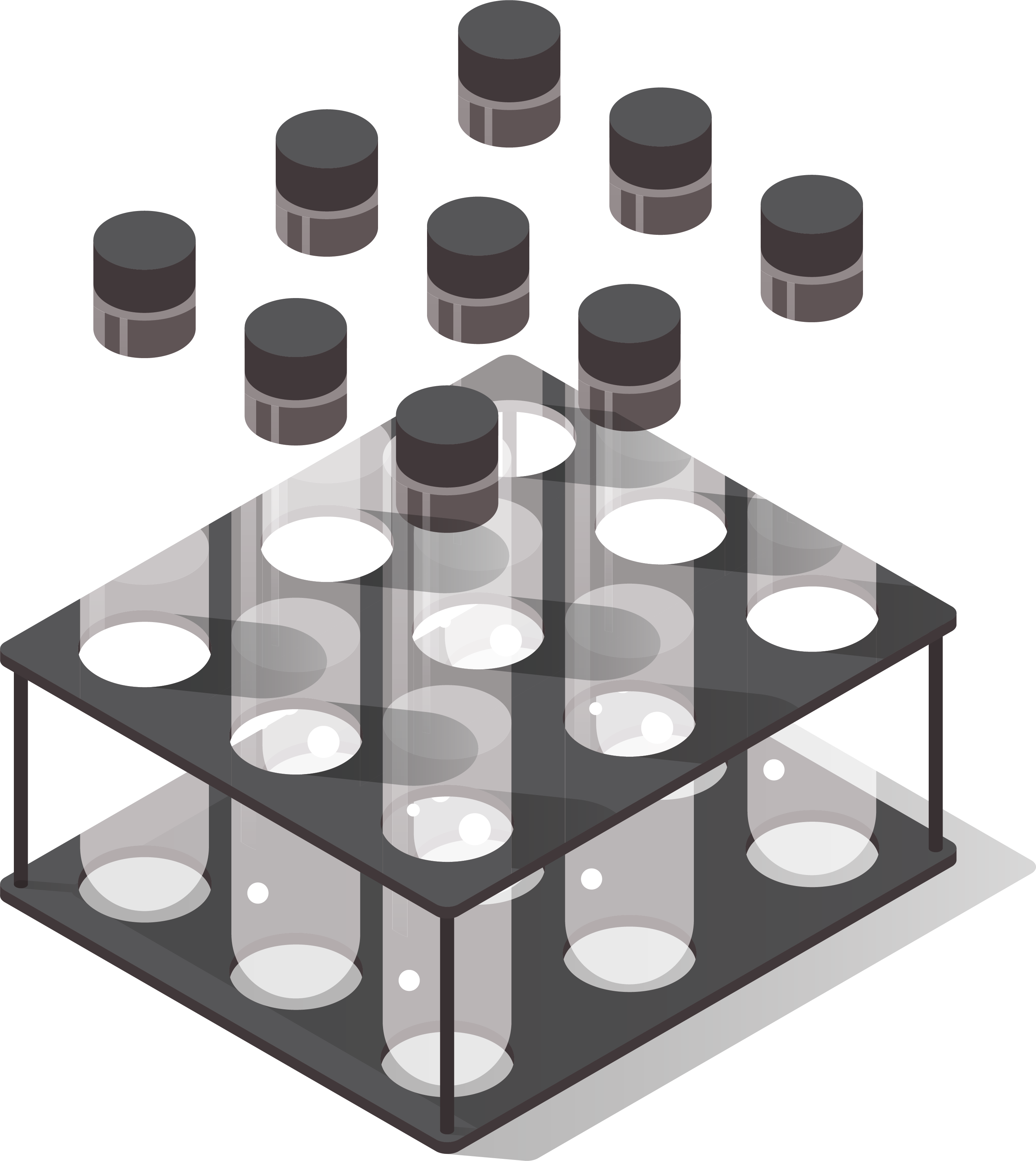

In order to keep up with the increase in production while strengthening our quality standards, a new 2400 m² testing laboratory was opened in early 2019. It is completely dedicated to checking our milk powders, and employs 80 people (qualified technicians, engineers, microbiologists and doctoral students) who perform 1 million checks each year, 250 tests on average for each batch produced.

Our technicians’ know-how combined with the certifications obtained, enable us to master the AOAC, ISO and GB analytical methods that we use in the best interests of our customers.

This infant milk powder testing laboratory has obtained COFRAC accreditation for testing according to ISO 17025, no. 1-6898, for the services mentioned on www.cofrac.fr

It guarantees the laboratory’s high level of technical competence and, above all, the reliability of its test results. This confirms very high standards in terms of product quality, hygiene, food safety and traceability.

people assigned to product quality, i.e. 14% of the workforce

tests for each batch produced

tests performed each year

In order to ensure the complete safety of our infant formula milk powders, we perform thorough inspections on over 300 machines. To achieve this, our teams work with experts and international researchers to implement inspection plans that are designed to meet the most stringent standards in force. Our clear goal is to maintain increasingly high standards in terms of quality, hygiene, health and safety, and traceability.